In the dynamic world of vaping, aesthetics play a pivotal role in shaping consumer preferences. From sleek metallic finishes to vibrant color gradients, the appearance of vape pens can significantly impact their appeal. One question that often arises among vape enthusiasts is, “How are these captivating color gradients achieved?” In this comprehensive guide, we’ll explore two common methods used to apply color gradients in vaping: anodizing and spraying.

What is CMF?

CMF, which stands for Color, Material, and Finish, is a fundamental concept in industrial design that influences the overall look and feel of products. In the context of vaping, CMF plays a crucial role in shaping the aesthetics of e-cigarettes. The choice of color gradient, material, and finishing technique can significantly impact the perceived value and appeal of vape pens. By understanding the principles of CMF, vape manufacturers can create products that resonate with their target audience and elevate their brand identity.

What Is Gradient Color?

Gradient color, also known as color progression or color ramp, refers to a design technique where colors transition gradually from one shade to another. This creates a visually appealing effect that adds depth and dimension to vape pens. Whether it’s a subtle fade from light to dark or a bold ombre effect, gradient colors can make vape pens stand out in a crowded market. By harnessing the power of gradient color, vape manufacturers can create products that captivate consumers and leave a lasting impression.

1. What Is Anodizing: More Than Just Oxidation

Anodizing is a surface treatment process that involves creating an oxide layer on metal surfaces to enhance their durability and appearance. While it is commonly associated with aluminum, anodizing can also be applied to other metals such as titanium and stainless steel. In the context of vaping, anodizing is used to create vibrant color gradients on metal vape pens.

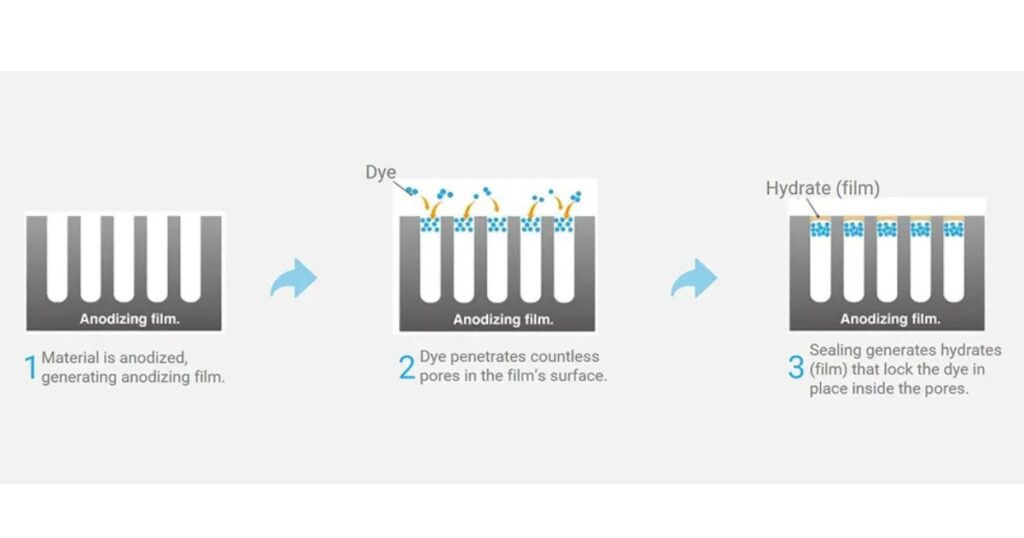

How Anodizing Works

During the anodizing process, the metal surface is immersed in an electrolytic solution and subjected to an electric current. This causes oxidation to occur, forming a thick oxide layer on the surface of the metal. The porous nature of this oxide layer allows for the infusion of dyes, which penetrate the metal and create the desired color gradient.

Benefits of Anodizing in Vaping Aesthetics

- Durability: Anodized finishes are highly resistant to corrosion, scratching, and fading, making them ideal for vaping devices that are subjected to frequent handling.

- Versatility: Anodizing allows for a wide range of color options, from bold primary hues to subtle pastel shades, giving manufacturers the flexibility to cater to diverse consumer preferences.

- Customization: With advancements in anodizing technology, manufacturers can achieve precise and intricate color gradients, enabling them to create unique and eye-catching designs that set their products apart from the competition.

2. What is Spraying: The Art of Atomization

Spraying is a surface coating technique that involves atomizing paint or coating materials and applying them to a substrate using a spray gun. This method is commonly used in industries such as automotive, furniture, and, of course, vaping. Spraying offers a versatile and cost-effective way to apply color gradients to vape pens.

How Spraying Works

In the spraying process, liquid paint or coating material is pressurized and atomized into tiny droplets using a spray gun. These droplets are then propelled onto the surface of the vape pen, where they form a thin, uniform coating. By adjusting factors such as air pressure, nozzle size, and spray pattern, manufacturers can achieve precise color gradients that transition smoothly from one hue to another.

Advantages of Spraying in Vaping Aesthetics

- Uniform Coverage: Spraying allows for even distribution of paint or coating material, resulting in a smooth and consistent finish that enhances the overall appearance of vape pens.

- Cost-Effectiveness: Compared to other finishing techniques, spraying is relatively inexpensive and can be scaled up for mass production, making it a cost-effective option for vape manufacturers.

- Customizability: With the ability to mix and blend different colors, as well as adjust spray patterns and techniques, manufacturers have virtually limitless options when it comes to creating unique and customized color gradients for their vape pens.

3. The Diverse Aesthetic Processes of E-cigarette Finishes

In addition to anodizing and spraying, the e-cigarette industry offers a plethora of aesthetic processes to choose from. From two-color injection molding to UV printing, vape manufacturers have a wide range of options at their disposal when it comes to finishing their products. Here are some of the most popular aesthetic processes in the vaping industry:

- Anodizing

- Spraying

- Two-color injection molding

- Stickers

- UV printing

- Skins

- 3D curved glass

Comparison Between Different Finishing Techniques

Each finishing technique has its own set of advantages and limitations, and the choice of method ultimately depends on factors such as cost, durability, and desired aesthetic outcome. While anodizing and spraying are popular choices for achieving color gradients in vaping, other techniques offer unique benefits that may be better suited to certain applications.

ALSO READ: Backwoods Vape Dab Pen Instructions and Review

In Conclusion

In conclusion, the application of color gradients in vaping is a creative and innovative process that requires careful consideration of various factors such as material, technique, and consumer preferences. By leveraging techniques such as anodizing and spraying, vape manufacturers can create products that not only look visually stunning but also reflect their brand identity and ethos. Whether it’s a sleek metallic finish or a bold ombre effect, color gradients play a crucial role in shaping the aesthetics of vape pens and captivating consumers in a competitive market.

Elevate Your Vape Brand with Custom Solutions!

FAQs

What is CMF?

CMF stands for Color, Material, and Finish. It plays a critical role in product design, especially in e-cigarettes.

How is gradient color achieved in anodizing and spraying?

Gradient color is achieved by controlling the dyeing process in anodizing and adjusting spray patterns and techniques in spraying.

Why are anodizing and spraying popular choices for e-cigarette finishes?

Anodizing and spraying offer benefits such as durability, customizability, and cost-effectiveness, making them popular choices for achieving color gradients in vaping.

Are newer processes for e-cigarette finishes always better?

Not necessarily. While newer processes may offer innovative features, tried-and-tested methods such as anodizing and spraying remain popular until newer techniques prove their effectiveness and integration into production.

Which method gives a more metallic finish, anodizing or spraying?

Anodizing often results in a metallic sheen, while spraying can offer a softer gradient. Both methods have their own unique aesthetic characteristics and applications in vaping aesthetics.

Lucas Steele is an experienced professional with 10 years in education. “Teachbullit” is his domain, reflecting expertise in teaching and learning.